Call : 08045479681

Vacuum Conveying Lean Phase

200000.00 - 2000000.00 INR/Piece

Product Details:

X

Vacuum Conveying Lean Phase Price And Quantity

- 5 Piece

- 200000.00 - 2000000.00 INR/Piece

Vacuum Conveying Lean Phase Trade Information

- 1-2 Piece Per Month

- 4-6 Week

Product Description

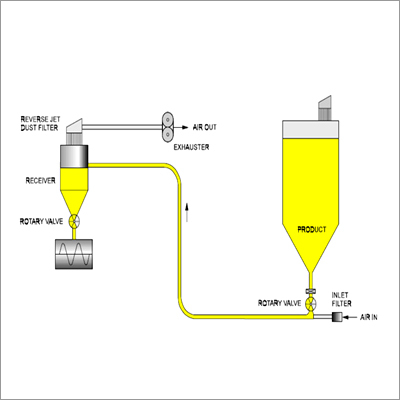

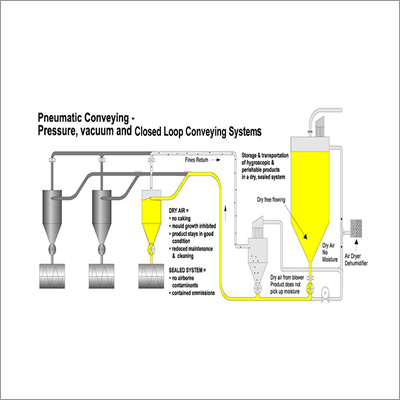

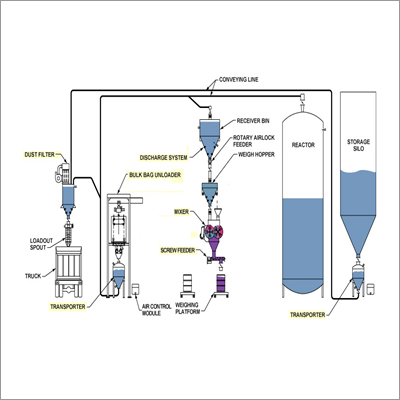

Vacuum Conveying Lean Phase is a highly efficient and gentle method of transporting bulk materials, such as powders, granules, and pellets, from one location to another using a vacuum pump. The system creates a low-pressure environment, allowing the material to be conveyed through a pipeline at a controlled rate. This method is widely used in various industries, including food processing, pharmaceuticals, chemicals, and plastics, for its ability to handle delicate and friable materials without causing degradation or segregation.

Frequently Asked Questions (FAQ):

Q: How does Vacuum Conveying Lean Phase work?

A: Vacuum Conveying Lean Phase works by using a vacuum pump to create a negative pressure or vacuum in the pipeline. This negative pressure draws the bulk material into the pipeline from a feed hopper or storage vessel. The material is then conveyed at a controlled rate to the destination point, such as a receiving hopper or process equipment.

Q: What types of materials can be conveyed using Vacuum Conveying Lean Phase?

A: Vacuum Conveying Lean Phase is suitable for a wide range of dry bulk materials, including powders, granules, flakes, pellets, and other free-flowing materials. It is commonly used for conveying materials in the food, pharmaceutical, chemical, and plastics industries.

Q: What are the advantages of Vacuum Conveying Lean Phase?

A: The advantages of Vacuum Conveying Lean Phase include gentle material handling, minimal product degradation or segregation, dust-free operation, and the ability to convey materials over long distances and through complex routes.

Q: Is Vacuum Conveying Lean Phase suitable for hygienic applications in the food industry?

A: Yes, Vacuum Conveying Lean Phase is widely used in hygienic applications in the food industry. The system is designed with smooth and easy-to-clean surfaces, ensuring compliance with food safety standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pneumatic Conveying Systems' category

|

BACT INDUSTRIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry