Call : 08045479681

Sugar Handling System

200000-3000000 INR/Piece

Product Details:

X

Sugar Handling System Price And Quantity

- 5 Piece

- 200000-3000000 INR/Piece

Sugar Handling System Trade Information

- 1-2 Piece Per Month

- 4-6 Week

Product Description

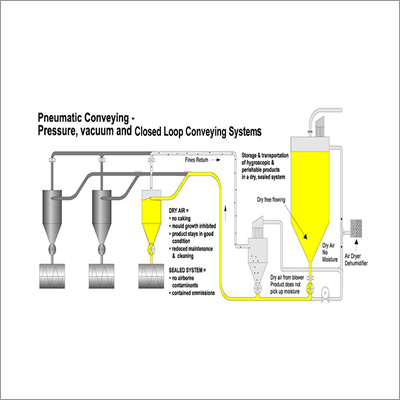

Sugar Handling System is an automated and efficient solution designed to transport, store, and handle sugar in bulk quantities. The system typically includes equipment such as conveyors, elevators, silos, and dust collection systems to ensure the safe and hygienic movement of sugar throughout the production process. Sugar handling systems are widely used in the food and beverage industry, as well as in sugar refineries and processing plants, to streamline operations and maintain product quality.

Frequently Asked Questions (FAQ):

Q: What is a Sugar Handling System?

A: A Sugar Handling System is a set of automated equipment and machinery used to transport, store, and manage sugar in large quantities within industrial settings. It enables the efficient movement of sugar from one point to another while ensuring safety and sanitation.

Q: What types of equipment are typically included in a Sugar Handling System?

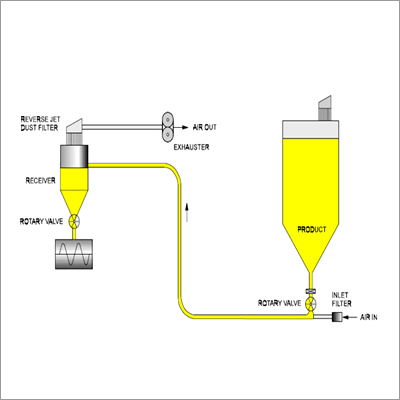

A: A Sugar Handling System may include various components such as screw conveyors, bucket elevators, belt conveyors, pneumatic conveyors, silos, bins, and dust collection systems. These components work together to facilitate the smooth flow of sugar throughout the production process.

Q: How does a Sugar Handling System handle sugar safely?

A: A Sugar Handling System is designed with safety features, such as enclosed conveyors to prevent sugar spillage, dust collection systems to capture airborne sugar particles, and safety interlocks to avoid overfilling of silos. These measures ensure a safe working environment and prevent product contamination.

Q: What are the benefits of using a Sugar Handling System?

A: Using a Sugar Handling System offers several benefits, including increased productivity, reduced manual handling and labor costs, minimized product loss, improved hygiene and cleanliness, and consistent product quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pneumatic Conveying Systems' category

|

BACT INDUSTRIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry