Call : 08045479681

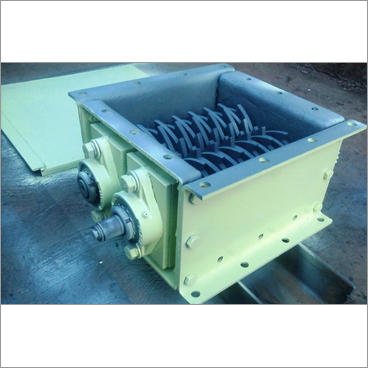

Lump Breaker

80000-1000000 INR/Piece

Product Details:

X

Lump Breaker Price And Quantity

- 80000-1000000 INR/Piece

- 5 Piece

Lump Breaker Trade Information

- 2 Piece Per Month

- 6-8 Week

Product Description

A lump breaker, also known as a lump crusher or lump disintegrator, is a robust industrial machine designed to reduce agglomerated or compacted materials into smaller particles. It operates by breaking down lumps, clumps, and chunks of various substances, such as chemicals, minerals, food ingredients, and pharmaceuticals. The lump breaker's efficient crushing action enhances material flow, improves processing efficiency, and ensures consistent product quality in industries like chemical processing, food production, mining, and recycling.

FAQs:

Q: What is a lump breaker?

A: A lump breaker is a heavy-duty industrial machine used to break down and crush large, agglomerated, or compacted materials into smaller particles, facilitating smoother material flow and enhancing downstream processing.

Q: In which industries are lump breakers used?

A: Lump breakers find application in diverse industries, including chemical processing, food and beverage, mining, cement, pharmaceuticals, recycling, and many others that handle bulk materials with lumps or agglomerates.

Q: How does a lump breaker work?

A: A lump breaker typically consists of rotating blades or crushing elements that shred or crush the oversized or compacted materials. The lumps are reduced in size, allowing the processed material to flow more efficiently through the production line.

Q: What are the advantages of using a lump breaker?

A: The key benefits of using a lump breaker include improved material handling, enhanced processing efficiency, reduced clogging and blockages, consistent product size, and reduced downtime in production processes.

Q: Can lump breakers handle different types of materials?

A: Yes, lump breakers are versatile and can handle a wide range of materials, including chemicals, minerals, food ingredients, plastics, pharmaceuticals, and more, regardless of their hardness or density.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Auxiliary Equipment' category

|

BACT INDUSTRIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry