Call : 08045479681

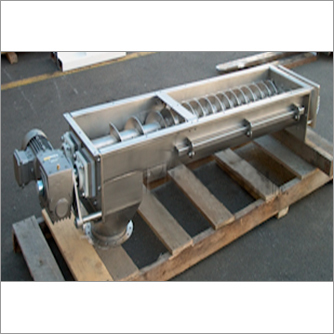

Gravity Feed Diverter

50000-300000 INR/Piece

Product Details:

X

Gravity Feed Diverter Price And Quantity

- 5 Piece

- 50000-300000 INR/Piece

Gravity Feed Diverter Trade Information

- 5 Piece Per Month

- 6-8 Week

Product Description

A gravity feed diverter is a versatile equipment used in material handling systems to redirect the flow of bulk materials through gravity. This device utilizes gravity to control the direction of material flow, allowing smooth and efficient transfer from one conveyor or chute to another. Gravity feed diverters are widely employed in industries such as agriculture, mining, food processing, and logistics, offering a cost-effective and low-maintenance solution for managing material flow in various production and distribution processes.

FAQs:

Q: What is a gravity feed diverter?

A: A gravity feed diverter is a mechanical device used in material handling systems to redirect the flow of bulk materials through the force of gravity. It ensures efficient and controlled material transfer from one conveyor or chute to another.

Q: In which industries are gravity feed diverters used?

A: Gravity feed diverters are utilized in a wide range of industries, including agriculture, mining, food processing, pharmaceuticals, recycling, and logistics, where bulk material handling and transfer are essential.

Q: How does a gravity feed diverter work?

A: Gravity feed diverters operate by utilizing the force of gravity to guide bulk materials along the desired path. The device features a movable flap or gate that diverts the material flow from one conveyor or chute to another, depending on the production requirements.

Q: What are the advantages of using a gravity feed diverter?

A: Some key advantages of using a gravity feed diverter include efficient material transfer, simplified material handling processes, reduced manual intervention, low energy consumption, and minimal maintenance requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Auxiliary Equipment' category

|

BACT INDUSTRIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry