Call : 08045479681

Cyclone Dust Filter

100000-500000 INR/Piece

Product Details:

X

Cyclone Dust Filter Price And Quantity

- 100000-500000 INR/Piece

- 5 Piece

Cyclone Dust Filter Trade Information

- 3 Piece Per Month

- 6-8 Week

Product Description

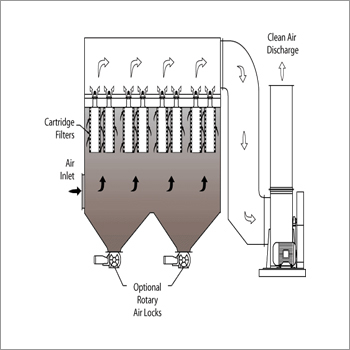

Cyclone Dust Filter, also known as a cyclone separator, is an efficient and cost-effective air pollution control device used to remove particulate matter and dust from industrial processes and ventilation systems. The cyclone works based on the principle of centrifugal force, where contaminated air is directed into a cyclonic chamber, causing the dust particles to be separated and collected by centrifugal action. Cleaned air is then discharged, and the collected dust is typically collected in a separate bin or hopper.

Frequently Asked Questions (FAQ):

Q: What is a Cyclone Dust Filter?

A: A Cyclone Dust Filter is an air filtration device that uses centrifugal force to separate and remove dust and particulate matter from industrial air streams, providing a more efficient and cost-effective solution for air pollution control.

Q: How does a Cyclone Dust Filter work?

A: The Cyclone Dust Filter operates by directing contaminated air into a cylindrical or conical chamber, creating a swirling motion. The centrifugal force causes heavier dust particles to move toward the walls and spiral downwards, separating them from the air stream. The cleaned air continues upwards and is discharged, while the collected dust falls into a separate collection bin.

Q: What are the advantages of using a Cyclone Dust Filter?

A: Cyclone Dust Filters offer several advantages, including simple design, minimal maintenance, low energy consumption, cost-effectiveness, and the ability to handle large volumes of dust and particulate matter without requiring filter replacement.

Q: Is a Cyclone Dust Filter suitable for handling fine dust particles?

A: Yes, Cyclone Dust Filters can effectively handle a wide range of dust particle sizes, including fine dust particles. However, for some applications with very fine particulates, additional filtration may be required.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Particulate Air Pollution Control Systems' category

|

BACT INDUSTRIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry